DermaMed: The Industry’s Leading Adhesive Tapes Manufacturer

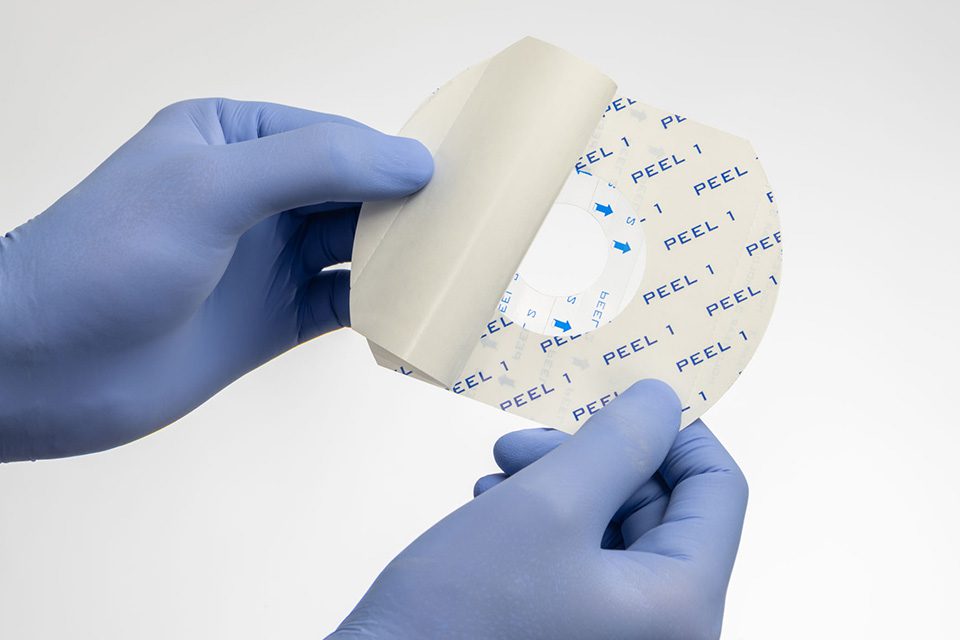

Adhesive tape solutions are essential in wound care, surgical disposables, wearables, and other stick-to-skin applications. By working with DermaMed, a medical adhesive tapes manufacturer, you’ll have peace of mind knowing you’re getting. We also provide expertise in product customization and product testing.

Products

Pressure-sensitive adhesive medical tapes have been crafted using advanced technologies to meet the unique needs of our customers. As the leading adhesive tapes manufacturer, our materials are comfortable yet reliable enough to provide a secure hold across many healthcare applications.

Capabilities

Leverage our adhesive material knowledge, longstanding supplier partnerships and state-of-the-art manufacturing to advance your business. Using industry-approved modern technology, we can provide an extensive range of specialized adhesives materials for various medical applications. As an ISO 13485 certified company, our stringent quality controls, rigorous testing protocols, and commitment to providing superior customer service make us stand out.

Engineering Solutions

Tap into our team of industry specialists. From product concept to the selection of specialized materials, we are a ready resource and partner. Our experienced professionals ensure that each client receives high-quality products with proven results. We will be with you every step of the way as we create and innovate the next ground-breaking product.

DermaMed is a Turnkey Medical Adhesive Tape Supplier

As a reliable adhesive tapes manufacturer, we’re focused on introducing adhesive solutions to the market that improve wound care, surgical disposables, wearables, and other stick-to-skin applications. Here’s how we do it.

Absorbents

Breathable Films

Foams

Laminates

Polyester Films

Polyethylene Films

Transfers Films

Make Us Your Go-To Adhesive Tapes Manufacturer

DermaMed is committed to providing our customers with products that meet the highest quality and safety standards. As the adhesive tapes manufacturer businesses trust, we ensure that all our materials and processes comply with regulatory requirements for medical adhesives. Our production facilities employ stringent quality control procedures to guarantee industry-leading performance in every product we produce.

Customization

Consultative Approach

Access to the Best Materials and Market Trends

Working on Long-Term Accounts In it for the Long Haul

Investing in Opportunity

While other manufacturers are willing to do custom work, the required quantities and upfront costs are often prohibitive. DermaMed is willing to invest in you and believe in your product. We are highly invested in the latest technologies and materials, allowing us to provide state-of-the-art solutions that meet the most demanding application requirements.

Knowing where the demand lies within your industry will also help you stay competitive and identify new areas of opportunity for innovation. Choose DermaMed as your adhesive partner today! Our dedication to quality, customization, and innovation makes us the perfect choice; choose us as your medical tape manufacturer.

DermaMed specializes in producing high-performance, pressure-sensitive adhesives and coated materials for medical applications.

We build adhesives systems and coated materials for medical applications ranging from wearables to electrodes, surgical drapes to complex wound care, from postnatal to geriatric applications.

We’re engineers and entrepreneurs — a partner to take your adhesive tape from concept to market.

Our Process

DermaMed is a business-to-business adhesive tapes manufacturer. Our customers are medical device OEMs who market their products through distributors or directly to hospitals. We work with design engineers who develop the actual product and the required materials for the intended product.

Our adhesive manufacturing process is designed to be efficient and effective, ensuring maximum value for our customers at every step. From concept through prototype design and ultimate implementation, we provide full support from start to finish.

Consultation

Product Solutions

Testing and Modifications

Production

Launch and Delivery

Once the customer approves the adhesive components, our teams work to ensure the timely delivery of adhesive materials for product launch and market availability. Our commitment to quality assurance ensures that adhesive solutions meet all industry regulations and expectations regarding reliability, performance, cost, and time.

DermaMed offers superior adhesive solutions that will exceed customer requirements while providing maximum value at every step—from concept through production and delivery. Contact us today to discuss why we’re the medical tape manufacturer that can help you achieve your objectives.